Dicing Film

MPE performs nearly all dicing with wafers and substrates mounted to dicing film. We offer UV dicing film for most applications, and we also have standard “blue” dicing film. MPE always UV-exposes UV dicing film before product is returned so that the customer may easily remove die from the film.

MPE performs nearly all dicing with wafers and substrates mounted to dicing film. We offer UV dicing film for most applications, and we also have standard “blue” dicing film. MPE always UV-exposes UV dicing film before product is returned so that the customer may easily remove die from the film.

We can write serial numbers, wafer ID, or any other information on the dicing film to help with traceability and part identification.

UV Dicing Film – UV dicing film consists of a polyolefin base layer with an acrylic adhesive containing a photosensitive additive. UV dicing film has strong adhesion to most wafers and substrates during dicing. After dicing is complete, the film is briefly exposed to UV radiation. The UV exposure significantly reduces the adhesive’s bond and allows parts to be easily removed from the film. The high adhesion of UV dicing film allows for very small parts to be diced and significantly reduces the likelihood of die detachment during dicing. Our UV films are also designed with anti-static properties. MPE inventories Ultron 1043R and Nitto DU-300 UV dicing films.

Blue Dicing Film – Blue dicing film consists of a PVC base layer with an acrylic adhesive that is not photosensitive. Blue film offers moderate adhesion to most wafers and substrates during dicing. The adhesion is generally strong enough to avoid die detachment during dicing while allowing for easy part removal after dicing is complete. MPE uses blue dicing films in some situations where a unique surface chemistry or surface properties interact poorly with UV dicing film. MPE inventories Ultron 1009R blue dicing film.

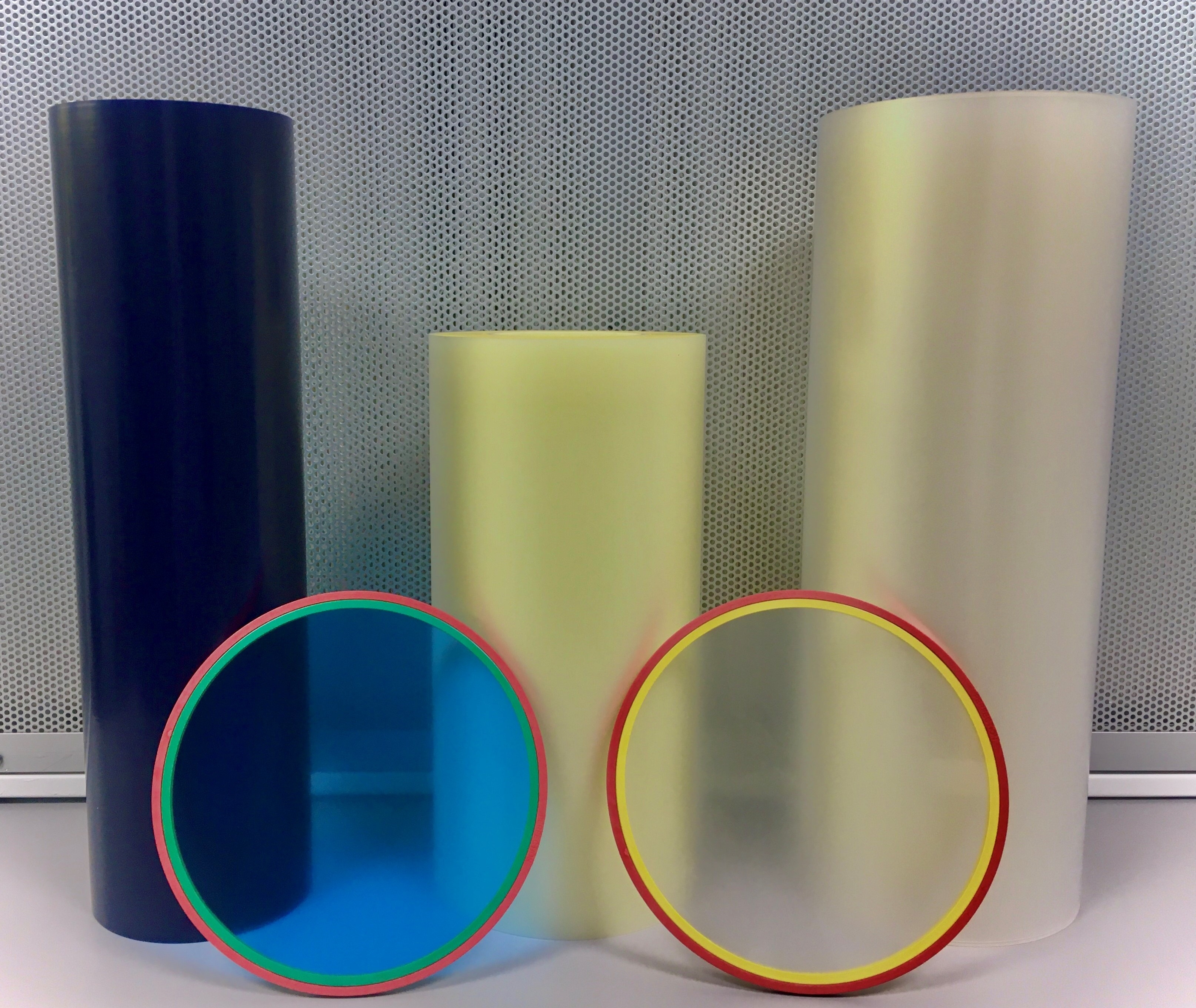

Grip Rings, Frames, and Shippers

Dicing film is held taut in a grip ring or frame before mounting the wafer. The wafer stays mounted in the ring/frame while on the dicing saw and while the individual die are picked from the film after dicing. MPE typically uses two-piece plastic grip rings or stainless steel frames. For each grip ring or frame size, we stock clamshell shippers. Repeat customers may return rings, frames, and shippers to MPE for re-use on subsequent orders.

Below are the dimensions of four grip ring size options:

| Assembly Inner Diameter | Assembly Outer Diameter | Thickness | |

|---|---|---|---|

| 4” (100mm) Grip Ring | 5.520” (140.2 mm) | 5.981” (151.9 mm) | 0.24” (6 mm) |

| 6” (150mm) Grip Ring | 6.689” (169.9 mm) | 7.322” (186.0 mm) | 0.24” (6 mm) |

| 8” (200mm) Grip Ring | 8.856” (224.9 mm) | 9.498” (241.2 mm) | 0.24” (6 mm) |

| 12” (300mm) Grip Ring | 13.006” (330.4 mm) | 13.640” (346.5 mm) | 0.24” (6 mm) |

For any additional questions about our wafer dicing services, please call us at 1-877-MPE-DICE, contact us via email, or fill out the request a quote form.

The above image shows our packaging for our four inch, six inch, and eight inch grip rings. The image also shows the 12 inch stainless steel frame and shipper.